Thordon Bearings has today welcomed the announcement by classification society ABS to award Approval in Principle to the “sterntube-less ship” concept developed in cooperation with the Shanghai Merchant Ship Design & Research Institute (SDARI), the National Technical University of Athens (NTUA) and Thordon Bearings Inc.

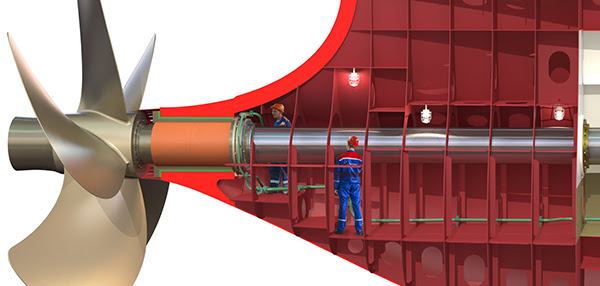

The revolutionary design replaces a vessel’s sterntube with an irregular shaped chamber that allows a shorter, water-lubricated propeller shaft to be inspected and maintained while the vessel is afloat, without having to withdraw the shaft in drydock.

While the concept completely eliminates the need for oil-lubricated sterntube seals and bearings – a major source of marine pollution – the design is likely to save shipowners hundreds of thousands of dollars in capital and operational expenditure over a vessel’s lifespan.

Speaking ahead of an ABS-organized seminar in Athens during the Posidonia trade fair, Anthony Hamilton, Technical Director, Thordon Bearings, said the concept “revolutionizes the ships’ traditional sealed propeller shaft”.

“We started wondering why a vessel with a water-lubricated shaftline needs a sterntube. Why couldn’t the shaft simply run in the larger space outside the sterntube? This space is designed into virtually all vessels where an oil-lubricated sterntube is traditionally exposed to seawater for cooling. With a water-lubricated shaft this space still exists but it’s wasted space.”

Hamilton said the space could be used to access the shaft for inspections, and a lot of the shaft installation and operational challenges “completely disappear”.

A sterntube-less ship features a shorter shaft with the prime mover further aft the vessel. An additional bulkhead seal and a torsional vibration damper would be required but there is no aft seal and Thordon’s COMPAC seawater lubricated bearing replaces the oil-lubricated bearing aft.

A sterntube-less ship features a shorter shaft with the prime mover further aft the vessel.

“ABS and the Technical University of Athens have done the math and the engineering behind it. They’ve looked at system pressures, temperatures, loads, noise and vibration levels, shaft alignment – everything works,” said Hamilton.

Craig Carter, Thordon Bearings’ VP Business Development, said: “There are huge savings here. You would never have to withdraw the shaft again, which can cost $100,000 plus in drydocking costs alone. We are not changing the design of the ship or the stern but by moving the engine further aft we free up more space for cargo.”

Dr. Chris Leontopoulos, Director Global Ship Systems Center, ABS Athens, said: “The use of seawater to lubricate the propeller shaft is well-established but the proposed design takes this further by removing the sterntube, decreasing the shaft line length, reducing engine room space and increasing the cargo space. It enables significant efficiencies and cost savings for operators.”

Thordon Bearings is taking shipowners, shipbuilders, repairers and members of the maritime press on a virtual tour of a sterntube-less ship on the Thordon (Technava) booth 3.111, during the Posidonia trade show, which takes place this week, in Athens, Greece.

Source: Hellenic Shipping News