In the maritime industry, communication at sea has lagged far behind the onshore world in terms of connectivity. There is a gap in the wired world. Even as continents have become more connected, the oceans that carry 80% of the world’s traded goods have been an afterthought, with satellite communications bearing the traffic burden and fleet operators paying big money for the pleasure.

Part of that barrier to information flow can be addressed by IoT – the Internet of Things, smart devices that can communicate via the internet about their status, which parameters they are running and almost anything else that can be measured by a meter or activated by a solenoid. In maritime, IoT devices can communicate position, telemetry data and device status back to shore for remote monitoring and measurement.

Even small data transactions can be expensive when they have to be beamed up into orbit and back, but now there’s an affordable solution and it comes cloaked in familiar technology, high frequency radio. Telenor Maritime have just acquired KNL Networks, who have been building an independent, global network to do what no one else has been able to do: provide reliable worldwide connected ships to shore with military-grade security.

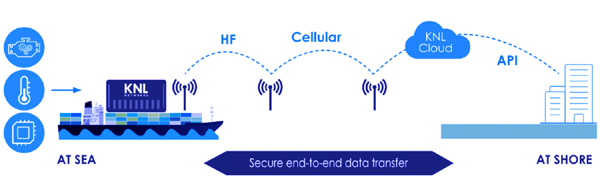

The result is an end-to-end solution that allows operators to connect with and collect data from instruments, onboard equipment and systems. The data can then be processed, formatted and sent via a revolutionary mesh network to data center on shore.

It doesn’t stop at simply recording instrument read-outs, according to Juho Jaakola, Head of Maritime Systems at KNL. Much more is possible as part of the process of digitalization that is sweeping the industry.

“We try to make it as easy as possible and a lean as possible process to start with the customer. We can take the most important data and start, for example, on monitoring fuel flow instrumentation in real time. But more and more, this kind of technology becomes an advantage in your operations. By using the data in your decision making you will get the benefits of reducing the operating costs and that will, of course, give you a better position against your competitors in the market at the same time ensuring compliance with new regulatory requirements.”

At the heart of this system is the mesh network and the flexible capability to gather and process data from the vessel infrastructure. Development has greatly improved the speeds and reliability of data communications over high frequency radio and the result is a secure, robust two-way connection range of up to 10,000 km giving ship owners and operators a full visibity and transparency to their oprations – for the first time in the history of shipping.

It’s the maritime communications industry game-changer everyone has been waiting for. For systems, telemetry and IoT devices, at least, there’s suddenly no need to integrate into ship’s IT systems and allocate congested satellite capacity to new applications, but a dedicated secure end-to-end channel for business critical data can be established.

And there are no capital expenditures involved, either. Telenor’s addition of the revolutionary IoT radio and data network to its existing world-class services is offered as an all-inclusive, per-vessel subscription. The subscription includes the hardware, gathering data from onboard systems and data package with updates and maintenance, eliminating all upfront costs and data overages. It is flexible enough to start with a single vessel, let it pay for itself and scale-up later across the fleet. It is easy to install and seamlessly integrates with existing on board systems. Indeed, its genius is that it is device agnostic. It understands all the equipment and systems that are capable of relaying information to it, even if the systems in question are legacy systems. This means that the solution is future-proof for all equipment onboard.

Imagine the possibilities of an onshore crew, a real-time team that augments the abilities of crew on the bridge with all the data seamlessly, securely shared between ship and shore. That kind of integration, according to KNL’s Jasmin Al Amir, is one of the key advantages to their current client base.

“I think that one of the unique selling points is that it is an open platform, which in essence, means we can integrate or take data from any type of machinery that you might have onboard, whether it’s legacy machinery or the newest technology and we harmonize the data between vessels enabling ship owners and operators to use comparable data over a fleet of mixed type of vessels. So, in that sense, we’re not manufacturer specific when it comes to, for example, different types of pressure transmitters or anything like that. And we can feed the data onto anyone’s software with best available algorithms to analyse the data – all in standardized ISO format making the solution future proof and easy to adapt to.”

Source: Maritime Executive